Marc Sommerfeld has worn a lot of hats in his journey through woodworking. He did 17 years as a high school shop teacher. He worked as a cabinetmaker cabinetaker. He became a dealer and did demonstrations all over the country at woodworking shows. Finally he started making some of his own tools and became what he is today: a tool designer.

Along the way, he learned a lot. From his students, he learned how to communicate well with a wide variety of people and to solve problems quickly. He also developed the quickest, easiest ways to accomplish certain woodworking tasks?because with teenagers you don’t have much time.

As a cabinet maker, he learned even more shortcuts, but more importantly, he learned that he didn’t have the tools he needed. “When you’re doing woodworking, your whole life is spent coming up with better and easier ways to do things,” say Marc. That’s when he started making router bits for himself, because he needed bits for specific tasks. His recent 22 degree router bits are a good example. These lock router bits are great for making solid locking joints for cabinets that need to fit in strange corners.

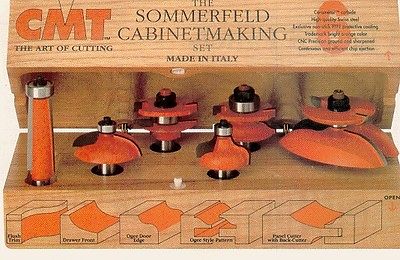

His designs caught the attention of CMT, one of the premier router bit manufacturers in the world. That company is based in Northern Italy and had recruited him as a salesperson and demonstrator for its line of bits. When the company saw what he was up to, it helped him turn some of his designs into reality.

With the weight and resources of a company like CMT, Marc has been able to design a lot of tools a lot faster than he could have on his own. This partnership has been a great fit for him, especially when CMT’s engineers help him design new tools and make them work.

About five years ago he developed a router table for himself, and now CMT has helped him build it and put it on the market. We would tell you more about this table, but it’s in our editor’s office and Rob said something about prying it from his dead cold fingers. We’re going to wait until he goes on another road trip and hope he hasn’t changed the lock on his office.

Marc says he became a tool designer by accident but we like the results. Marc still wears a lot of hats. He still does demos at woodworking shows. He also designs a lot of woodworking projects that compliment the tools he designs-so he still gets to do some woodworking. His miniature grandfather clock is a good example of that.

But in some respects, he is still a teacher at heart. He sees a lot more education going on in the woodworking industry-at shows, in special classes, in books and magazines-and he very encouraged by it. He sees the Baby Boomers beginning to retire and looking for training in the craft and great tools. Marc is prepared to provide both.

– Bob Filipczak