If there is a holy grail for those of us who want to spray but only have a small shop, little money, and weather that won’t let us throw open the windows, this may be it. Imagine an affordable tabletop spray booth that keeps you safe and legal while you spray, but recycles clean air back into the shop so that you don’t lose all your heat in the winter and air conditioning in the summer. Once you are done imagining, read on, because such a booth already exists. It’s from Spray Tech and is manufactured here in America.

“Spray Tech was started by Tyler Rand in 1994,” explained Steve Boda, the company’s national sales manager, “and he is still the president and owner. An engineer by training, Tyler became a representative for a company that was in the automotive frame equipment business. He and a friend started a business in eastern Pennsylvania as distributors, but Tyler decided he wanted to pursue an acting career. He moved to LA, and as with most nascent actors, had to get a job to stay alive. He starting working for a company that makes spray booths. In the early 1990s, he became part owner of a spray booth company, Spray Tech, and ultimately bought it.

“The current company occupies 59,000 square feet in Rialto, California, and is filled with state-of-the-art equipment. We have around 40 employees, distribute throughout North America, and are a leading manufacturer of spray booths serving the aeronautical, automotive, marine, industrial, government and wood industries. Our product line goes from small, four-foot booths to something big enough to handle aircraft and train cars. All our products are made right here in the U.S.

“On the small end, our tabletop booth comes in two styles: vented and carbon-filtered. The latter is for those situations where outside venting is not possible. Thus, you can have a booth in your shop that does not exhaust the air out of your shop while you are spraying. You can spray anything in it: shellac, lacquer, polyurethane and, of course, water-based finishes. While you spray, the carbon filtration units capture the VOCs and emit clean air back into the shop. Thus, you can spray in the winter without losing the heat in your shop, or spray in the summer with the air conditioning on.

“The carbon filter booth was designed by our owner and perfectly meets the needs of small volume users, like hobby and small shop woodworkers. Initially, it was created to help customers who were using spray cans, which, although many don’t realize it, should also be used in a booth. He calibrated the amount of charcoal needed for the VOCs generated, added standard filters to capture the overspray, and designed the booth to be as compact as possible.

“These table top booths come in four-, five-, six- and eight-foot widths, and with spraying heights from two to four feet. They can be mounted on your counter, or you can buy legs from us. Each booth comes equipped with fan, filters and a manometer, a tool that measures airflow to tell you when it is time to change the filters. Interior lighting is optional. Replacement filters are available on the open market, but frankly, we sell them direct for less than you are likely to find them elsewhere. Prices for these booths start at just under $2,000.

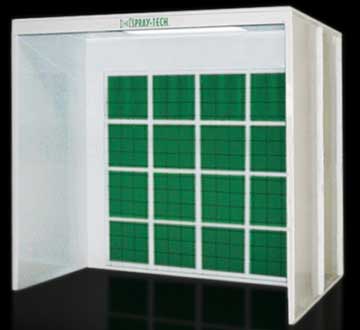

“If you need something larger, and can handle a booth that will exhaust the air outside, you can move into an open face booth. Designed for larger projects, it, too, captures VOCs and overspray. While the booth requires assembly, everything is included: steel panels, fasteners, lighting, filters, controls, exhaust stack, fan and manometer. They range from five feet wide, five feet deep and seven feet tall, to 20 wide by 10 deep and 10 tall. Naturally, custom sizes are also available. These larger booths start from $2,700 dollars and go up from there. Our best-selling open front booth is an eight by eight by seven foot deep booth, something large enough to accommodate just about any piece of furniture. It’s more or less the standard booth you will find in many furniture shops.

“The bottom line for woodworkers is that if you want to spray legally, you need a spray booth. It is neither legal nor green to simply open up the windows and blow overspray outside. Beyond that, a spray booth increases productivity by eliminating overspray, which in turn reduces the amount of hand sanding needed between coats. It also keeps your work area clean and safe. Bear in mind that water-based coatings also generate both overspray and VOCs, though less of them, so the reasons for needing a booth are valid for people who spray only water-based finishes as well.

“As far as freestanding, non-vented booths go, we are the leading manufacturer of this unique product. We are the only company in the U.S. with an engineered carbon filtration booth that does not require exterior venting and is big enough for woodworkers. Granted, you can find tiny booths designed for artists using air brushes, but they are generally way too small for woodworkers. The best way to buy our booths is direct from the company online, or by phone at 800-535-8196. If you call, you can talk to tech experts who can help you figure out which booth is right for your needs.

“While Spray Tech is a national company that is well known in the automotive industry, we want to become more familiar to woodworkers. We’d like to become their primary resource for high-end products they can depend on to help them comply with regulations and laws, and give them a cleaner, safer environment to work in.”