I recently purchased an older 10” Craftsman table saw (probably 30 to 35 years old). When I took possession of the saw, the cast-iron top was rusty, but it cleaned up very nicely. The problem I have is, whenever I cut pretty hard wood 1X (oak or maple) or 2X pine, I get about 2 to 3 inches into the cut and the blade stops. At first, I thought it was the blade, so I installed a new blade and got the same result. I had the motor checked out at an electric motor shop and the motor is fine. I cleaned the underside of the saw very thoroughly and sprayed a lubricant on the arbor, but so far nothing has helped. The wood is not binding the blade, the wood I’m cutting is dry. What am I missing? What more can I do? – Ken

Rob Johnstone: I am assuming that this is a single belt drive saw (a contractor’s saw?). If you think about it, there are two main factors that determine how much power gets to the saw blade. First: how much power is the motor delivering? It sounds like you tested that and it is fine. The second is how much of that power is effectively being transferred by the drive system. Cabinet saws often have three belts or a single super-robust belt to deliver the power to the arbor. I am guessing you have a single belt that may be slipping, either at the arbor or at the motor. Try replacing the belt. When the saw blade stops does the motor stop?

Another possible option, and I have to admit that I am going out on a shaky limb here, is that your electric circuit may be underpowered. This is likely not the case if your breaker is not popping.

Chris Marshall: I agree with Rob’s reasoning here. Sounds like the “transmission” is slipping somewhere — at the belt and pulleys or between the pulleys and the shafts they connect to (arbor and motor). The pulley/shaft connections shouldn’t be the issue unless there are no keyways on the pulleys or shafts to house a retaining key. When there’s no keyway, the only thing that typically holds a pulley stationary on the shaft is a setscrew or two, and that/those could loosen and cause the pulley to slip.

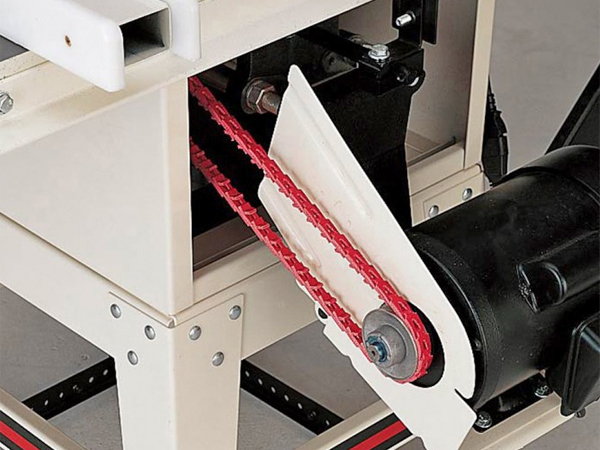

Drive belts dry out over time and lose their pliability, just like fan belts on a car do. My guess is, that’s where the slipping is occurring. For a saw as old as yours, I’d replace the belt just as a matter of course. And when you do, here’s a suggestion: replace the old belt with a segmented “link” belt. These belts can be a real blessing for a saw with a traditional V-type drive belt. The links connect together easily, and you can make a belt to suit any saw, regardless of the belt diameter, by just adding or removing links. They also help reduce belt noise and don’t take on the “memory” of the belt’s shape as they age. Definitely worth the upgrade! Here’s a link to learn more about them (click here).