A visit to Jerry Cole’s site reveals a company whose mission is clearly to make your table saw work better than you ever imagined it could. Whether you work on a contractor’s saw or a more elegant cabinet variety, In-Line Industries offers items that they insist will make a world of difference. There are easy-to-use alignment and adjustment tools, upgrades that make your saw run quieter and smoother, and a sled that lets you effortlessly cut any angle with dead-on accuracy.

It is this last item, dubbed the ‘Dubby,’ that started it all. There are other cut-off sleds and mitering devices, but as Cole puts it, “the Dubby is faster, safer, easier, more accurate, more versatile, and more fun than any other system in the country.” Personally, I’m inclined to agree; I’ve been a loyal Dubby user for some 15 years.

The company got its start somewhat serendipitously back in 1987. “I was working with a guy named Andy Volk who had a cabinet shop in a barn,” Cole recounted. “He had a homemade cutoff sled that he thought was special. He tried to make it prettier and patent it, but the patent attorney told him he couldn’t. I did the majority of the table saw work, and got sick of clamping a stop onto his sled, so I came up with a telescoping stop system. Andy went back to the attorney, but since patents can only be awarded to the inventor, he said ‘partner with Cole, or it is his.’ We created an 80-20 partnership, since Andy had all the money.”

“We made up some sleds, went to a show with them, and sold a few. One of the first purchasers said ‘You know, if you make that thing do angles, you’d have a real winner.’ We designed a Mylar scale and put it on the outer edge of the platform, and made the fence swing and lock through an arc in the platform. We then sent everyone who had purchased the first model this upgraded version. That’s how the Dubby was born.”

Simply put, the Dubby is a cross-cut sled that tracks in your table saw’s slot. “The advantage of a sled,” Jerry explained, “is that the wood is not moving on top of the saw. It remains stationary on the platform of the sled, so the material does not walk. It gives you a more controlled cut by eliminating the friction between the top of the saw and the wood being cut.” This easily adjusted sled allows you to do exceptionally accurate miters from zero to 68 degrees, though Jerry points out that beyond 45 degrees, the cut becomes more dangerous.

Over the years, the Dubby has been upgraded. Today’s version has a hold-down clamp for cutting small pieces safely, and the original Mylar scale has been replaced with an adjustable, acid-etched stainless steel scale. The backstop, originally made of wood, is now an aluminum extrusion with a wooden end that can be adjusted for zero clearance at any angle.

Meanwhile, back at the barn, the Dubby was about to change ownership. “Andy, who was a great cabinetmaker, really had no interest in building and selling these sleds. He wanted to do custom cabinets. I had just met Betty, the woman who would become my wife, and was dead flat broke, but I believed this thing would sell. She convinced me to buy Andy out, but he wanted $15,000, which was way more than I had. Betty suggested I offer $5,000 per year, with the proviso that he help build some initial inventory. Of course, I did not even have $5,000. Although she only had known me for six months, Betty handed me a check for five grand. We signed an agreement, and made up 77 sleds.”

“I got them all boxed up, and Andy said to store them in the loft in the barn. Frankly, he thought I would never sell them and they would be up there forever. I called Woodworker’s Supply of New Mexico and talked to one of the purchasers, who agreed to look at one. Once he saw it, he called back and bought 75 of them to put in their 1988 catalog. Andy could not believe it, but we made some more.”

“Then, I called Wood magazine and asked if I could send them a Dubby for their opinion. I sent them one, and they never called me back. I assumed they did not like it. One day, the phone rang, and someone said ‘I want to order one of those jigs I read about in Wood magazine.’ You could have knocked me over with a feather. They never told me they were reviewing it.”

“Their review said ‘We’ve never seen a more accurate miter fixture than this one. We recommend it for anyone interested in doing precision work.’ It also showed up in that year’s buyer’s guide. Soon, other woodworking magazines started reviewing it, too. That exposure got sales going, and gave me enough money to start buying booth space at woodworking shows. The rest is history.”

The Dubby really needs to be demonstrated for folks to understand it, so Jerry took it on the road. Even today, about 90% of them are sold at shows, and the rest go to people who are recommended by other owners. “Sometimes, simple is best,” Jerry insists. “At the shows, I let children set up the fixture to make 12-sided boxes as proof of how easy it is. You can’t beat if for convenience, versatility, and dead-on-the-money accuracy.”

These days, five people build the Dubby in a 2,800 square foot shop. Although the Dubby is the flagship of the line and the best selling of the lot, Jerry feels that the most important products are those that upgrade the performance of the saw itself. “When it comes right down to it,” he says, “the most important part of owning a table saw is making sure it is set up right. If it isn’t, nothing is going to work right on it.” That philosophy, combined with the problems of selling on the road at woodworking shows, was the instigation for the next In-Line product.

“When I started doing shows, my old 1976 Sears contractor’s saw made so much noise that I had trouble making myself heard, and besides, the pulleys kept coming loose. I had a machinist make me some better pulleys, and the noise was cut dramatically, so I started selling the pulleys as an upgrade. I figured that if the pulleys made that much of a difference, perhaps a better belt would also help. In 1990, a company representative from Fenner Drives dropped off a red link belt. I found it hard to believe, but it was like a different saw. The only noise you could hear was the whistle of the blade and a hum from the motor. I called the rep, and two weeks later, he joined me at a show in Portland, Oregon with a few boxes of the belts. There, we introduced the power twist belt to woodworking.”

Next came an awareness that most contractor saw owners have alignment problems. “If you own a saw where the motor sits out the back,” Jerry explained, “you will have alignment problems because there are vibration issues. We looked at the alignment products on the market and felt we could improve on them. We came up with a self adjusting bar that sits in any size table groove and allows you to accurately set up a saw, a drill press, a router table, and other tools as well.”

Still not satisfied, Jerry turned his attention not to measuring alignment, but actually making the adjustments. “One of the hardest things I ever tried to do was adjust my contractor saw the way all the manufacturers say to do it. It involves loosening the trunnion bolts, tapping the trunnion into position with a block of wood and a hammer, then locking it back down while praying that it does not move. But because the bolt threads catch on the trunnion, it will typically shift as you lock it down.

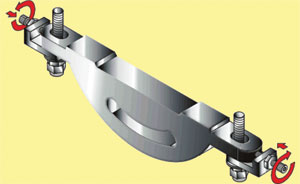

“To avoid that, we made up our ‘PALS’ kit. It contains a pair of studs that replace the bolts and two ‘L’ brackets that go over the studs. They have micro-adjusting screws on the legs to make sure the arbor shaft is perfectly square to the miter grooves. In 10 minutes, you can get your saw accurate to under one thousandth of an inch, and once it is locked down, it will not vibrate loose again. You no longer need worry about it coming out of alignment again. I have not realigned my saw since it fell off a truck at a show, and then it took me only five minutes to correct it.”

Though In-Line Industries is a small company, they are completely dedicated to making sure their products do what woodworkers need them to do. “If you set our products up, and use them as intended,” Jerry vowed, “you will see a complete difference in how your tablesaw works.”

That’s the sort of statement that means a lot more coming from a man who’s been personally demonstrating his company’s products since 1988. As Jerry succinctly puts it, “Everything we sell works.”