Their name may not be quite as well known as some of their competitors, but many people who have found out about the sandpaper and related abrasives sold by Uneeda Enterprizes Inc swear by both the company and its products. To get a line on the company and a bit of its history, I had a chat with the president, Bruce Fuchs.

“The company was founded by my father, Herman Fuchs, in 1967,” Bruce told me, “and he is still the chairman today. I became president, handling day-to-day operations, after working there for more than a decade. My father Herman had a background in woodworking, as did his father, a woodworker who came over from Eastern Europe in the late ’50s, finished school here and got a job with a company that sold abrasives.

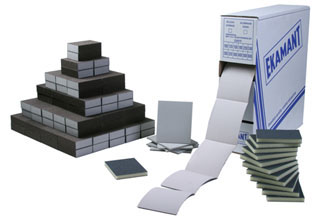

“Herman hooked up with the Ekamant product line, a Swedish company that has manufactured products specifically for woodworking since 1927. Uneeda is now the exclusive distributor for Ekamant in North America. Prior to 1967, Ekamant had no presence in the United States, but Herman felt the quality was very good and he felt the woodworking niche was one that was comfortable for him.

“When Herman started the business, he was working out of his uncle’s facility, which manufactured store fixtures. The store fixture company was called Uneeda, though I don’t know why or where the name came from. He incorporated under the name Uneeda Enterprizes to distinguish it from the store fixture business, but they continued to share some facilities. Back in those days, there was a Uneeda doll company, a Uneeda biscuit company – it was not an unusual name.” In fact, if you Google ‘Uneeda Enterprises, with an ‘s’ instead of a ‘z,’ you get an entirely unrelated company that sells cleaning products.

“Our current headquarters are in Spring Valley north of Manhattan in a 60,000 square foot facility with about 100 employees handling thousands of products. In terms of manufacturing, we import master rolls of abrasives and convert them into wide belts, narrow belts, discs, sheets, bushes, mops, sanding sponges and even non-woven abrasive pads. Four warehouses around the country support the distribution network and drop ship to customers directly.”

I asked Bruce what was different about the sandpaper he sells. “Our paper contains a more consistent abrasive that yields a higher quality finish,” he explained, “and the paper lasts longer as well. Ekamant uses the best quality grit, resins and backings, and their manufacturing technology allows them to be extremely consistent, resulting in very high quality abrasive products. The proof is in the pudding; some of the largest kitchen cabinet and hardwood floor manufacturers are using our products, and it is not because we are less expensive. We sell to some of the biggest names in the industry in cabinets, flooring and furniture.

“One of our newest products, for instance, is our UAOFR sanding discs, sold under the rubric Ruby Red. Until recently, abrasives were either cloth-backed or paper-backed. Within the past decade or so, people started putting grit onto polyester film backings. The problem with cloth is that because it is woven, it has peaks and valleys. That means the grit is not at as consistent a height. On a smoother surface, like paper or film, the grit tips are more consistent, which gives you a more consistent scratch pattern. When disc sanding, the film gives you the strength of cloth with the superior finish quality of paper. Film is much stronger than paper, and is less likely to tear. In short, it offers the advantages of both, giving you both a more consistent scratch pattern and longer abrasive life.

“Through the years, we’ve sold to all aspects of the market, but we don’t sell through retail stores: only to industrial suppliers. We focus primarily on industrial manufacturers and distributors who in turn sell to the industry. At present, we have dozens of distributors around the country, but aside from our website, all our marketing is direct. The best way to find a local distributor is to contact us directly via our toll-free number. If there’s no distributor in your area, we’ll sell direct. Our minimum order to buy direct is 100 dollars. While any shop can buy from us directly, most small shops are likely to go through one of our distributors, who also tend to carry other supplies for the woodworking market.

“Recently, we opened an online store which will sell to anyone, including individual hobby woodworkers. The store offers discontinued or overstocked products at bargain prices. That’s the only thing we sell online. Everything else is sold through our distribution network.

“The fact that we don’t sell in small packaging – our smallest package is 100 disks – often turns off small users. The sad thing is that if you look at price when buying in the sort of bulk we sell, the price per sheet is vastly cheaper than what most hobby woodworkers are used to paying at their local home improvement store.” Over time, it would be much cheaper to invest in boxes, since sandpaper does not go bad the way most finishes do.

I asked Bruce what sets Uneeda apart from other abrasives suppliers. “We sell only one superior quality level of abrasive,” Bruce pointed out, “no matter where you buy it. That’s not necessarily true for the entire industry. Some companies sell different qualities of papers to different buyer markets.

“If our sort of quality matters to you, contact us and we’ll direct you to our nearest distributor. You won’t find us at the local Lowe’s® or Home Depot, but once you find us, it’s easy to buy from us, and we think you’ll appreciate the difference.”