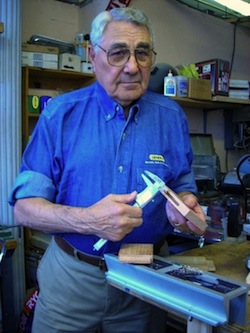

Two weeks ago, while visiting the General Tools & Instruments booth at the International Woodworking Fair (IWF), I had the pleasure of meeting Burt Weinstein. Burt is an ongoing consultant with the company and a key product developer for General’s line of woodworking jigs.

He’s also 84 years young.

“I was fairly retired some 20-odd years ago, but it seems I’ve been flunking ‘Retirement 101’ ever since,” Burt admits.

You may not know Mr. Weinstein, but you’ve probably seen his products in the pages of our magazine from time to time. Prior to May 2006, he ran a company called Simp’l Products that manufactured a line of inexpensive woodworking jigs intended to solve common joinery challenges. You might recall his Jointer Clamps, which attach to the edge of a waney or irregular-edged board and to a straightedge in order to facilitate safe, easy ripping. Or, maybe you’ve purchased one of his Laminatrol fence accessories for your table saw. It closes the gap between the fence and the saw table to keep thin plastic laminate from slipping underneath. Burt designed a doweling jig and a pocket hole jig, too. All of them were made of aluminum extrusions and other quality parts but sold (at that time) for around $40 or less.

“I co-founded the company back in 1989 after spending time in my friend Dick Deaton’s cabinet shop. Although I’m not a woodworker, I watched how Dick worked and wanted to design things to help him work better. The Jointer Clamp performed so well for Dick that he wondered if the product could be taken further, and so he and I partnered to start Simp’l Products.”

Burt and Dick’s philosophy was as simple as their company name suggested: they intended to take the mystery of out making solid woodworking joinery. Burt wanted to accomplish that goal with a variety of jigs that could be accessible to novices but still useful to the pros. And he set out to do it without costing woodworkers an arm and a leg.

“We had some ups and downs, mostly because our products were inexpensively priced. But, just because something doesn’t cost a lot doesn’t mean it’s poorly made. I’ve always considered cost control to be an engineering requirement of my products.”

In this day and age, where quality generally goes hand-in-hand with cost, Burt’s approach is a business objective worth getting behind.

Prior to the 1980s, product design was familiar country for Weinstein. In fact, it’s been his life’s ambition. Following his discharge from the armed forces in 1945, Burt enrolled as an engineering student at the University of Vermont and then at Johns Hopkins University. He was lured into starting his engineering career early by the Sta-Dri Company, which manufactured powered cementitious materials. Following WWII, the company was at a loss for equipment and brought Burt on board to help them get back on their feet.

“They hired me to build the building, then design the machinery to put in it,” Burt recalls.

Among other things, he developed an air entraining system for Sta-Dri that could blow powered materials and air through a much smaller pipe than was used at the time. That product’s success led to consulting work on air entraining systems in the flour manufacturing industry. There have been a variety of other jobs he’s taken through the years creating industrial solutions of one sort or another.

Burt’s accomplishments (some patented, others not) have been many and varied. An avid downhill skier, he invented two or three types of retractable ski bindings that were quite successful. In the boating field, Weinstein developed a Dolly Dingy, which allowed a boat to be carried on its side from storage to water. He also created a winch for sailboats. There have been product developments for the medical industry, too, including an endotracheal tube holder to keep patients from biting the tubing, plus a modified disposable syringe.

“I’ve been awarded maybe a dozen or so patents through the years…it’s hard to recall clearly these days.”

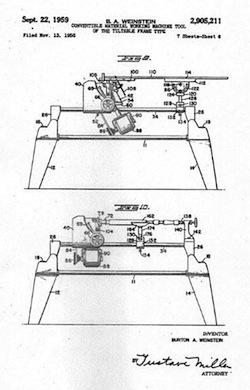

Burt’s first patent does come back into sharp focus for him. In 1956, he invented a combination woodworking machine with a tilting arbor that could be converted into a table saw, drill press or lathe. At the time, ShopSmith was also making them, but the table on their machines tilted rather than the arbor. (His original patent drawing is included here.) He sold that patent to the Tool Products Corporation.

Four years ago, while at the National Hardware Show, Burt met with Joe Ennis, CEO at General Tools & Instruments. Weinstein, then 80, was ready to sell Simp’l Products and retire (again); Joe wanted to expand General’s Product line into woodworking accessories. Synchronicity was at work: General bought the company, and Burt stayed on as a consultant. Dick retired and continues to do woodworking as an avocation — an actual graduate of “Retirement 101,” I can only presume.

Burt says his relationship with General Tools & Instruments has been a good one in the years since. In fact, aside from former Simp’l Products offerings updated to General’s E•Z Pro line, the company has brought a low-cost and unique dovetailing jig to market. It is Burt’s design. He’s now working out the details of an all-in-one E•Z Pro Mortise & Tenon Jig.

The product design process hasn’t changed much for Burt through the years. He still creates all of his mechanical drawings by hand on a drawing board, then passes them along to engineering staff at General to convert them into CAD renderings. “At this point in time, I have a CAD program, but I don’t think I’ll get around to learning it,” he quips.

At the conclusion of our interview, Burt left me with several reflections on the current state of woodworking product development.

“I’m not certain that the tool company consolidations of late are a good thing. I’ve always felt that more competition is better for the industry as a whole … It also seems that sometimes new products are directing woodworkers instead of the other way around. Some products are just ‘toes in the water’ to get something to market. They’re only half developed. Others are overly complicated; in my mind, more adjustments in order to use something are actually small failures. I try to make jigs for General Tools with minimal additional adjustments required so even a new woodworker can figure them out easily.”

“I’m very happy with General’s approach — making products available to more woodworkers at affordable prices. General is located here in New York City, where I live, so I can have a continuing and active relationship with them.”

So when does Burt anticipate easing fully into retirement? It’s hard to say. He says the ideas keep “finding him,” and he enjoys satisfying the need.

“Every time I complete a new product or get another patent, I tell my wife it will be my swan song. She says she’s heard it all before.”

He’s quite proud of the new mortising jig and feels it just might be his capstone invention. But then, in his next breath, he hints about a new jig that hasn’t even seen the light of day yet. “Chris, I have a lot of problems with the way biscuit joints are made …”

But, that will be a conversation for another day. And, considering Burt’s ambitions and tendencies, he’s probably already got drawings on the board for a sturdy, low-cost jig to install them better.

So it goes for a man with product development running through his veins.