Whether it’s a little magnetic cube you pop onto your table saw blade to dial in a bevel angle, a digital readout that helps you gauge your planer’s stock thickness or a calipers that displays in LCD … it probably has Barry Wixey’s logo on it. For seven years, Wixey has been a leader in developing affordable aftermarket accessories that make measuring easier. But his interest in digital solutions for woodworking goes much further back than that: more than 20 years.

Wixey says he’s pretty much always been a woodworker and active DIYer. His dad got him started in the craft as a child, and the enthusiasm never faded. He and his wife Cora built their home from scratch when the couple were just 25 years old. These days, when the two aren’t running their shared business from their home in Sanibel, Florida, or making routine trips to China to oversee the production of new measuring products, there’s always some kind of remodeling project going on.

Aside from his hobby interests, though, Barry’s professional background in tools and woodworking machinery extends all the way back to the early 1980s when he was a mechanical engineer for Stanley Tools. “I designed ratcheting wrenches and other products for them until 1987, then I took a position with Delta Machinery and worked there until 1995. After that there was a two-year stint where I was designing machines for DeWALT … you could say I’ve worked with a lot of folks in this industry through the years,” Wixey comments.

He’s also designed a lot of familiar machinery. When asked for a quick recall of some past projects, Barry mentioned three popular DeWALT planers: models DW733, DW734 and the award-winning DW735. He also played a role in creating DeWALT’s popular DW788 Scroll Saw, a 10-in. DeWALT miter saw, a 12-in. Delta lathe and a benchtop oscillating spindle sander.

“I’ve just always really loved the creative process of developing tools and machinery. I’m happiest in front of the computer doing CAD drawings for a new product or out in the shop making parts for a prototype of some sort. It’s what gets me out of bed in the morning and keeps this work interesting for me.”

Through the process of developing all of those machines, Wixey spent plenty of time on an airplane traveling to sources on the Pacific Rim. “Every one of my corporate jobs involved flying to Taiwan to negotiate and work with suppliers, as well as oversee production processes. Over the years, I became very knowledgeable about who could do the manufacturing work efficiently and at a high level of quality overseas. Eventually, I was often called on for that sort of consulting advice. It just went with the territory, I guess.”

Digital measuring technology came onto Barry’s radar back in 1989, while working on a new readout system for Delta table saws and planers. It was called EMS (Electronic Measuring System), first designed for use with Delta Unifences. It was well-received at the time as an add-on kit, but Barry recognized a few limitations to it. For one, it was only accurate out to about 40 inches, short of a 60-in. range that would have been a better solution for professional cabinet saw rail systems. It displayed in millimeters, decimal inches or fractions, but the fractional readout couldn’t account for fifteen-thousandths-inch distances between primary fractional readings. He wanted the fractional display to be accountable to within a few thousandths of an inch instead.

Still, many woodworkers saw the benefits of early EMS, even with some shortcomings. In talking with hundreds of woodworkers at the time, Barry saw room for much more than one application for digital technology for woodworking. It was the tip of a potential iceberg of new accessories.

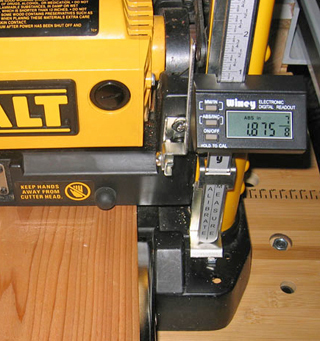

Around 2000, Cora challenged Barry that the couple should start an independent consulting firm, and it’s a company the two of them have run ever since. Initially, Barry helped design DeWALT’s DW735 Planer, but other clients included JET, Delta, RIDGID and Milwaukee Electric Tool. And, the startup business also gave him time to take EMS to the next level. He developed a new, patented system called Precise Fraction Technology that combines a decimal inch readout with fractions. The fractions only appear when almost precisely equivalent to the decimal inch readout, which Wixey says is four times more accurate than other fraction-only digital displays. It solved early EMS’s fractional readout limitations, and it ushered in the first Wixey-branded product: the WR500 Planer Digital Readout.

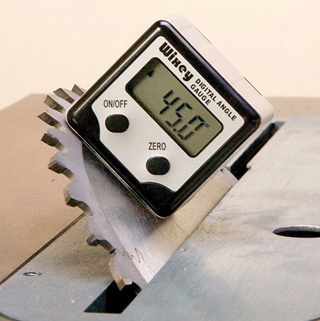

Response among woodworkers for the new planer accessory was enthusiastic, and major vendors such as Rockler Woodworking and Hardware were quick to add it to their product lines. Since that first rollout in 2005, Wixey Development has added 13 more digital accessories, including blade angle finders, digital protractors and calipers, rip fence indexing systems, height gauges and planer depth adjustment readouts. All of them feature Precise Fraction Technology. These days, Barry says the Digital Angle Gauge “cube” is the most popular item among hobbyist woodworkers, outselling the company’s next-best favorite, the WR 510 Planer Readout, by about ten to one.

While many woodworkers are coming to realize the value of digital measurement devices, there are still naysayers that argue that it’s simply overkill. Who needs to take readings in thousandths of an inch? But Wixey explains other virtues of digital besides extreme accuracy. “In woodworking applications, angles are just plain hard to set accurately on a tool. Digital simplifies the process and takes the guesswork out of it. It’s also easy to misread an Imperial scale and get your measurement or depth setting wrong. Digital tells you accurately, and you don’t have to count tick marks on a ruler. You measure once, cut once. And, our devices offer unbelievable repeatability. After they’re calibrated, you can set the exact same measurement on your machine today, tomorrow or a year from now and make the exact same cut.”

Barry credits the company’s small business approach as the reason why he and Cora can be almost immediately responsive to customers. Cora runs the website, Internet sales and sales service. “I personally handle every single technical service issue and can email photos, instruction manuals or sketches to help people understand our products … the feedback we get from our customers and the discussions we follow on woodworking web forums are where almost all of our new product ideas come from.” As examples, Barry mentioned his plans for converting most of the current product line from using wafer-type watch batteries to longer-lasting and easier to find AAA batteries, a frequent request from customers. A triple-A version of the popular Digital Angle Gauge is available now. He’s also developing a digital protractor that will emit audio measurements, too. That should come in handy for woodworkers as well as math students who are visually impaired or blind.

Wixey admits to having many more ideas for new digital products in the next few years, but he doesn’t rule out the possibility that history could even repeat itself. “I would love to design machinery again as well. I’ve already got ideas for a table saw and planer … with digital readouts, of course.”