In our last issue we visited one of the many finish suppliers here in the U.S. That inspired a few of our Canadian readers to remind me that many American finishing products are not shipped across the border.

To make amends to our northern neighbors, I’m devoting this issue’s Industry Interview to a Canadian finish supplier, but not just any supplier. As owner Jeff Richardson says about his company, “Wood Essence is the ‘go to’ company for the finishing materials you can’t find elsewhere in Canada.”

The reason for the company’s very existence goes back to Jeff’s own frustration at being unable to find what he needed for high quality finishing. During years spent working in other fields, he never gave up woodworking as a hobby, and finding the “right stuff” was often a problem.

“In high school, I did a lot in industrial arts,” Jeff recounted, “especially woodworking, and over the years I always did woodworking as a hobby. I began working in construction after high school, but soon switched over and became a machinist for a number of years. While machining, I got turned on to CAD, so I started a business selling AutoCAD systems and training people to use them, and did that for 18 years. I sold the company in 2001 feeling it was time to move on to something else.”

Fortunately for Canadian woodworkers, that something else turned out to be supplying hard-to-find finish materials. “As far back as 1997, I had been trying to find finishing products that I liked and that would create the finishes you see in magazines. These were not the sort of items that you find at a big box store. Even when I found them, it was tedious and difficult to get them up here in Canada. In fact, I hear something similar from my customers every day. They often phone and say they are shocked to find these items here even now.

“Shellac flakes, colored waxes, dyes, grain filler and pigment concentrates were rare as hen’s teeth around here, so I decided to make them available to others. I opened Wood Essence in Saskatoon, a city of about 200,000 people in the heart of Saskatchewan, and quickly became the conduit for specialized American and European finishing products into Canada.”

In case you were wondering, the name Saskatoon comes from the Cree Indian name for a local indigenous berry. If you go there, you might find the berry, but don’t bother looking for a walk-in store. Jeff’s business is a two-person company with a warehouse and a web site, but no storefront. That allows him to concentrate on selling only specialized items that he feels are worth handling, both in terms of usefulness and quality.

“We started with only three or four products: dyes, shellacs and fillers,” Jeff explained, “but soon added waterborne finishes, which I see as the future of finishing. The trend is for customers to switch to waterborne finishes both for their own safety and for environmental reasons. Since then, we’ve added waxes, pigments, gel stains and even spray equipment, and will continue to add products as our customers request them. We are a niche market and intend to stay that way, so don’t expect to ever see us carry the products you find at the local hardware or home store.

“Currently, we carry Mixol universal pigment concentrates, Target waterbased finishes, pore fillers, various grades of shellac, paste waxes in all colors and Bartley gel stains and finish. In addition, we offer Mirka abrasives, Walcom spray guns and DaVinci brushes from Germany. Though they are actually made as artist’s wash brushes, used for applying backgrounds on entire canvases, we find these DaVinci brushes work superbly for waterbased coatings and shellac, the only two brushable finishes we sell.

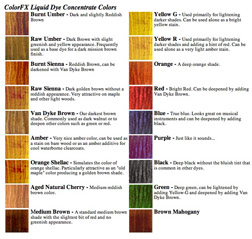

“One exclusive product line is our ColorFX dyes, which is our own brand of liquid dye concentrates. As far as I know, we are the only ones in Canada offering this sort of thing. They are very convenient, easy to use and mix, and will go into a wide variety of materials. There is no need to wait for powdered dyes to dissolve or to pre-mix anything. You can simply add them, a drop at a time, to get exactly the color you need in a wide range of compatible mediums.”

It seemed clear that Jeff’s business was aimed squarely at folks just like himself, and he was quick to confirm that. “Although I do have some professional shops as customers,” he admitted, “my main focus is primarily the semi-professional and hobby woodworkers who are more particular about the finishes they are after.

“At the typical home store, people tend to settle for what is available rather than getting exactly what they need. For example, you can’t find grain filler or dyes at a home store, but you can at Wood Essence. Here, we offer the specialty items that they could be using, and perhaps most importantly, a lot of good advice on what to use and how to use it. In part, that is because we don’t have online ordering, which means we get to talk to most of our customers directly by phone. That allows us to make certain they are getting finishes that suit the task and are compatible with their other products. It also gives us a chance to do a good bit of teaching.

“One of the things that is most painful to me is to hear back from a customer who has put together an ill-conceived finishing schedule that has resulted in a disaster that looks awful or is peeling off like cellophane. To forestall that, we listen to our customers, answer their questions, and make recommendations that we feel will result in finishing success for them. My biggest recommendation, of course, is for all of my customers to test every finishing material first, especially if they are planning on pairing our finishing materials with something they have bought elsewhere.

“People often build a complete project and wait until their last day before considering their finishing schedule, and because of that, frequently end up disappointed with their results. I recommend they spend 10 or 15 minutes at the end of every day during the building of the project testing and practicing with whatever finish materials they have chosen. That way, by the end of the project they have worked out all the bugs, know what to expect and know that everything works.

“This, of course, implies that you should envision the finish at the same time you first envision your project, and work on the two simultaneously. A bonus of this approach is that you end up with a finish sample in hand, done on offcuts of the wood you are using for the piece itself. After all, it is wisely said that if you are not experimenting on scraps, you are experimenting on your project.

“The odd thing is that people routinely use scraps to check the settings on their table saw, router and so on, yet will not use those same scraps to try out their finishes. My advice is to spend a few minutes with your finish. It will pay off.”