Jim Sannerud’s Scandinavian heritage has been an inspiration for his woodworking. He went into business on his own in 2003 and, shortly thereafter, decided to learn woodturning with the idea of making spindles for chairs.

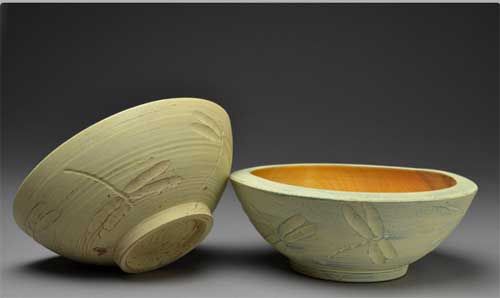

“I found out there’s a lot more you could do with woodturning,” Jim said. For example, historically there have been a lot of turned Scandinavian wooden ale bowls. “I started to research that, and that led to carving spoons, and that led to research of different kinds of folk art,” he said.

Jim both builds his own pieces and studies others’, frequently taking trips to Europe to do so. “Most of the time I’m meeting with people who are working actively,” he said. “Being able to spend time with people is the main way I learn.” He also likes to leave his travel schedule flexible enough to take advantage of opportunities that may arise, like attending an exhibition of wooden bowls in southern Sweden or, on his most recent trip, earlier this summer, visiting the national museum in Stockholm’s exhibit on wooden chairs. “I just show up, and there’s all the information I need,” Jim said.

He does pursue formal learning opportunities as well, having taken classes from both Swedish master craftsman Willie Sundquvist and Willie’s son, Jögge Sundquvist, as well as Beth Moen, the recent recipient of Sweden’s highest honor bestowed upon a woodworker.

While the classes Jim takes are taught in Swedish, he said most of the instructors do speak some English – and he relies on the universal commonality of woodworking, and his own observations, as well.

His preference for the Scandinavian style of woodworking is in part personal – “It’s a connection to the past. I have distant relatives there, and I recently walked where my grandfathers walked” – and in part aesthetic. “I like the style of the Northern European countries,” he said. The hallmark of visible tool marks ties in to both areas.

“A lot of things today might as well have been turned by a machine rather than a human being,” Jim said. “When you’re studying Scandinavian, you can tell there was a human being there. You can tell what the tools are that they were using. Sometimes I can even tell, like if they were using a gouge, what hand they were holding it in.

“I’m interested in not-so-perfect things, things that are not so sterile,” Jim said.

His own work has developed over the years; for example, although he has always done surface embellishment, his carvings have moved away from traditional symbols toward his own interpretations.

His preferred wood, birch trees from Minnesota’s North Shore along Lake Superior, makes a nice carving wood, Jim said. Wood from trees that grow in northern Minnesota, he said, has a different feel than those grown elsewhere, due to climate. “It’s a slower growth tree, so it’s a bit harder than what we find down here in the south [of Minnesota],” he said. “It has a nice balance between the hardness and the softness of the wood.”

Another important aspect of the wood Jim works with is that it’s green, fresh-cut wood. “Taking fresh-cut logs and turning them into something takes a bit of knowledge,” he said, which is why he is participating as a speaker and workshop instructor at a Fresh Cut event held at Minnesota’s North House Folk School in October. “It’s a meeting of people working with, or interested in working with, fresh-cut material, all green wood,” Jim said.

Jim enjoys both learning and teaching, and exploring through the objects he makes. “I don’t ever get too attached to the things I make. I’m more interested in the making of things than hanging onto them,” he said.

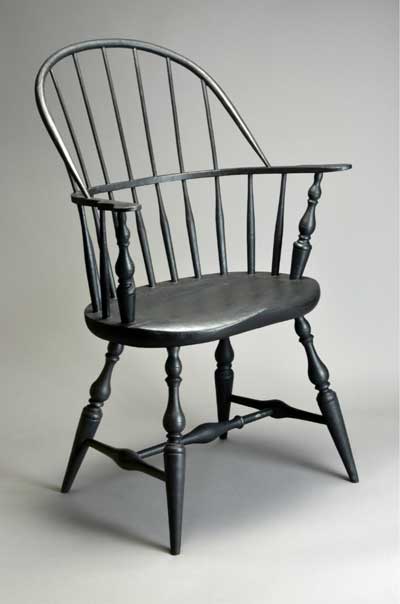

There are, of course, a few exceptions – like his first-ever woodworking project, a bubblegum machine made in the basement hobby shop of his 4-H leader when Jim was about nine, and the bowls, spoons – and, most recently, the chair – he made in classes with Beth Moen. (Jim designed the chair to fit in an old suitcase and brought it back to the U.S. in parts, with plans to glue it up once he got it home. He did do a dry assembly in Sweden first to make sure the pieces fit together accurately.) Those items, he said, remind him of the things he learned in class, as he continues on his learning path.