No matter how experienced you are with a table saw or how much you believe that injuries can be avoided by just staying alert, they still happen with alarming frequency. The Consumer Products Safety Commission estimates that 54,800 table saw accidents occur annually. And more than half of all workshop-related amputations — 52.5 percent — were the result of table saw mishaps in 2015.

There are more than 12 million table saws in use in the United States, with about 250,000 more sold every year. So, while a ballpark of 50,000+ injuries might be a relatively small number within the grand scheme of things, the injuries suffered are often permanently debilitating and can even be life-threatening.

What’s the solution to making table saws safer to use so that those statistics can both diminish and one day even be eliminated? Bruce Wang, acting CEO of Micro Jig, believes there’s a three-pronged answer: better safety products, better education and better training. He’s so certain of this, in fact, that the company has a mission to eliminate table saw injuries altogether by 2020.

“Preventing 50,000 table saw accidents per year within three years is entirely possible,” Wang says. “This represents less than one half of one percent of the total number of table saws in use in the U.S. We (at Micro Jig) have the technology, products and education now to prevent these injuries on a wide scale.”

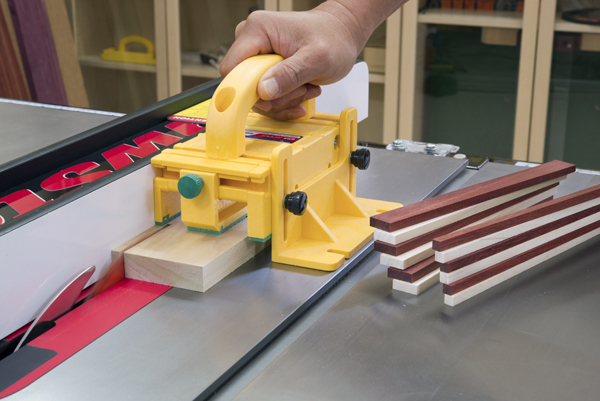

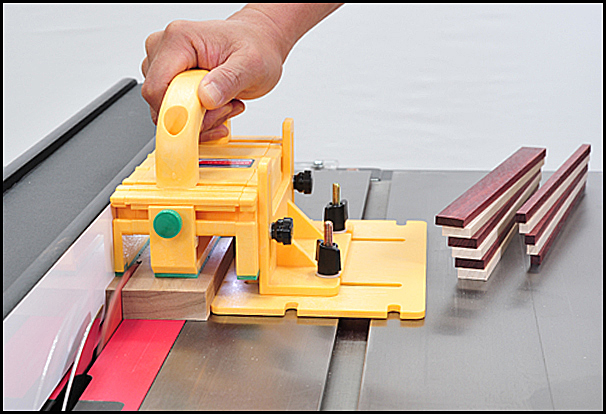

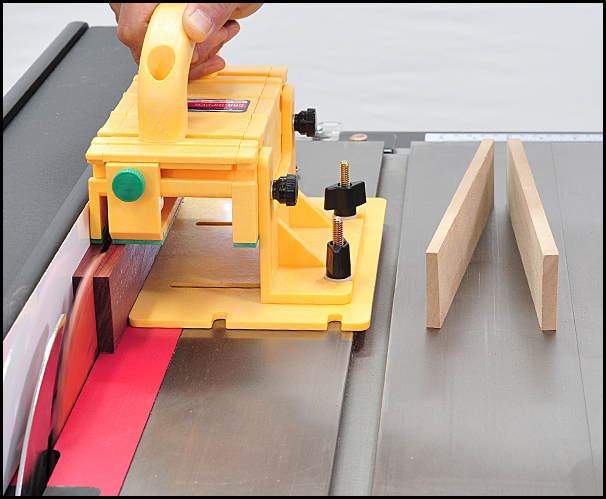

The company’s GRR-RiPPER®, which Wang’s father invented in 2001 when he founded the company, addresses the two most pressing and dangerous aspects of using a table saw: finger amputation and kickback. You’ve no doubt seen GRR-RIPPER advertised and used in publications and online for many years. It’s a plastic and rubber handheld pushing device that straddles the blade and controls both the keeper piece and the offcut during rip cuts. Wang points out that the device effectively controls the three vectors of force required to feed material through a table saw: it provides downward pressure against the saw table, inward pressure against the rip fence (during rip and groove cuts) and forward pressure to advance the workpiece. GRR-RIPPER’s raised handle design also keeps the “feed” hand shielded from the blade.

“The cost (of a GRR-RIPPER) is very affordable, especially when compared to the expense associated with injury,” Wang says.

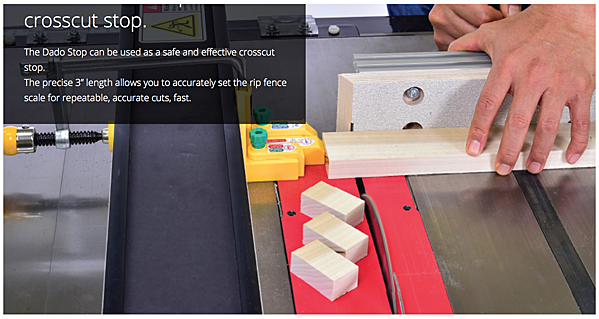

Another more recent safety product — Micro Jig’s MATCHFIT™ Dado Stop — is an indexed stop block that provides clear space between the rip fence and the blade for cutting dadoes or making through cuts. During a crosscut, Dado Stop enables an offcut to fall away from the blade instead of binding between the rip fence and blade, where it can jam, catch the blade teeth and be propelled backward violently.

“Not only does (Dado Stop) provide safety to users who purchase (it), but it also creates broader awareness, potentially prompting users to create their own stop blocks to prevent crosscut kickback,” Wang adds.

Developing better safety products is only part of Micro Jig’s solution. A change in public mindset about table saws is also sorely needed, Wang believes. “The industry as a whole has become complacent, turning a blind eye as table saw injuries continue to happen, year after year … The concept that losing one’s fingers is a necessary risk of table saw use is prevalent in the woodworking community.”

But Wang is quick to recognize that a segment of the saw manufacturing community is addressing table saw hazards head-on: SawStop’s flesh-detecting table saws are making significant inroads in preventing accidents, and they have been for a long while. He adds that Micro Jig not only supports the technology but also uses several SawStop saws in its shop. Even so, the technology comes up short, in terms of its ability to impact the entire table saw industry, for a couple of reasons. For one, economically priced benchtop table saws account for 75 percent of the table saw market, some priced as low as $129. SawStop’s most economical model, at more than $1,300, is cost-prohibitive for many users.

He also cites the recent restriction of Bosch REAXX saws to the U.S. market as another problem that limits access to flesh-detection technology. The outcome of that litigation makes flesh-detection “dependent on SawStop’s exclusive distribution channels,” Wang says.

Wang believes that flesh-detecting technology will eventually be included in every new table saw. “It’s only a matter of time,” he adds. But the timeframe for replacing some 12 million table saws with flesh-detecting versions could take decades. “Relying on skin-sensing/blade brake technology alone is unlikely to solve the problem swiftly.”

So, in the meantime, Micro Jig is setting out to change awareness about table saw usage by providing better general education — and it’s available to everyone. “We’re working with our retail partners to do in-house safety training around table saws. We’ve also created a library of safety content available free on our website and YouTube channel. And, we’ve partnered with the most influential woodworkers in the world, sharing and spreading a message of safety and educating users on how to properly operate their machinery,” Wang says.

He hopes this will provide a substitute for the table saw training that used to happen in school woodshop programs, which continue to be on a programmatic decline. Micro Jig’s educational resources can also provide a clearer, safer approach than crowd-sourced learning that’s happening through Internet sites such as YouTube. While that might be the most effective and widely distributed form of table saw training these days, “depending on the source, viewers may be learning wrong, unsafe techniques,” Wang says.

Even with better safety devices and training, every saw user must be his or her own safety advocate, too. Wang offers several suggestions: find a mentor who is willing to teach you the fundamentals of table usage. Both woodworking clubs and woodworking stores are also good resources for learning how to use a table saw more safely. And if you turn to online content as a tutorial, be sure to follow sources “who really know what they’re talking about,” Wang adds.

He also suggests buying a GRR-RIPPER and using it faithfully.

“With proper care, tools and training, using a table saw can be a very safe activity,” Wang says. “I like to compare it to rock climbing which, early on, was very dangerous. But new tools and training were developed, and now the sport is enjoyed by both young and old with very little risk of serious injury … We (at Micro Jig) see a future where you can tell someone you’re a woodworker, and they don’t immediately ask you if you still have all your fingers.”

Learn more about Micro Jig products and educational resources by clicking here.