Yorgen Kvinsland says he’s always been artistic, to the point where he ended up in art school, working with ceramics and glass. “The woodworking aspect,” he said, “has been my livelihood.”

For a while, Yorgen was a cabinetmaker for a living, but “I felt like that was a bit limiting design-wise: you have to follow the box and a door” framework. His father provided him with the idea to focus on art doors instead.

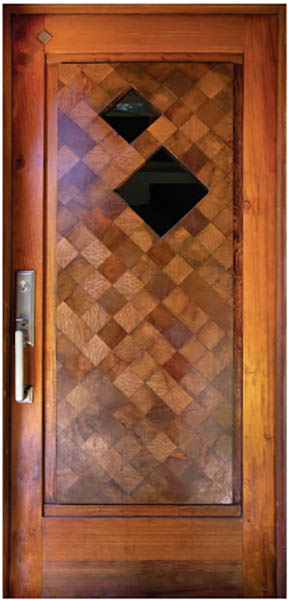

Doors artistically have more room for expression than cabinets, Yorgen said, with the only parameters being that a door must open, and it must fit into the space allotted for it. “It’s the focal point of the house,” he said. “The door is so important, because it’s the first thing you see when you enter the house and the last thing you see when you leave.”

In his work with doors, one of the things Yorgen tried to do was to make panels out of end grain, in an attempt to focus on what he saw as an underutilized aspect of wood, as well as to make the visible the age of the tree through the growth rings. With the first door he made, he also incorporated rondel glass, mouth-blown circular pieces that Yorgen describes as having rings “kind of like tree rings.”

Although that particular panel experienced more wood movement than he anticipated, resulting in the need to replace the panel, Yorgen remains committed to his goal to “push it beyond the standard door. I’m more interested in making things people haven’t seen before.”

Right now, this means that he is more interested in making doors on spec, rather than custom pieces – and that he is splitting his business into a door-focused section and a division with a broader focus, so that he can explore other projects.

For instance, right now Yorgen is exploring the use of a CNC router, in collaboration with both Laguna Tools (the supplier of the CNC) and his brother, a CAD technician. “He programs the computer; I make the parts,” Yorgen explained. He’s also making videos documenting his work with the CNC.

His interest is in exploring the CNC router as “not just a cutout machine, but for actual 3D pieces.”

“A lot of people have a strong reaction to the CNC machine. They see it as a competitor in the carving world,” Yorgen said. “I don’t use it to make carvings. Way back at the time the table saw first came into use, I imagine people thought the table saw was ‘cheating.’”

“You’re not going to use a CNC machine to round over edges; you’re going to reserve a CNC machine for places you really need to use it. There’s still a place for other tools: I use a chisel all the time; I use a chainsaw all the time.”

Right now, Yorgen is using a CNC in building a project entitled “Rest It Nest,” which he describes as a “glorified tent” treehouse constructed of wood. The sleeping platform with queen size bed includes a cable that raises and lowers the piece to hoist it up into the trees.

“There’s a ton of angles that have to be resolved, that are super-ultra-tricky,” Yorgen said. The CNC’s capacities, he added, allow working with multiple strange angles, whereas, “You just wouldn’t do it” in traditional woodworking.

The Rest It Nest is a combination of steel and wood, and Yorgen’s studio in general is mixed media, with a focus on wood as the primary material. Most of that wood is in some way involved with sourcing, he said.

“I try to stay clear of woods from afar. I don’t see much reason to do that when wood from here is so incredible.” In his California location, Yorgen finds that he enjoys working with hydrone and cypress, as well as old growth redwood harvested by a friend’s former spouse when it was allowed to collect the wood from the state’s rivers. (It’s no longer allowed, due to the disturbance of salmon habitat.) “I’m helping her mill it up into what woodworkers can use, and in the process of milling and grading, I have first pick of whatever material I want to use,” Yorgen said.

Whatever he is making, whether a public bench shaped with a chainsaw and adzes (the other in the set was shaped with the CNC), or wooden backs for cell phone covers for the new Runcible round cell phone, Yorgen says he’s interested in pushing woodworking to a new level. “Traditional is good, but there’s also more that can be done.”