Aside from the higher initial cost, it’s hard to criticize a table saw that detects contact with your skin in order to save you from a catastrophic blade injury. But, since 2004, SawStop has been the only manufacturer from which to choose in the skin-sensing table saw market. This fall, however, the brand options are about to expand by one, when Bosch’s much-anticipated GTS1041A REAXX™ Portable Jobsite Table Saw becomes available to the public.

Critics of SawStop’s dominance in this market segment will surely feel that fair competition is long overdue. And, Bosch intends not only to help more users avoid accidents, but also come out of the gate with an exceptional product to challenge SawStop’s Jobsite Saw, which launched in March.

“We’ve engineered the Bosch 10-in. REAXX Portable Jobsite Table Saw to offer users the best injury mitigation system available in the power tool industry,” says Craig Wilson, product manager for REAXX. “There’s a heritage in jobsite table saws that Bosch has spent decades building, and users will find that this saw maintains that high standard.”

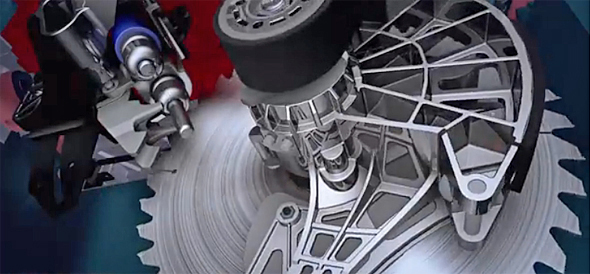

At the heart of REAXX is Bosch’s Active Response Technology™. The saw’s built-in computer uses a low-voltage, low-current electrical signal that’s imparted into the saw blade. When human skin touches the blade, the electrical signal is altered in a way that creates a unique electrical “signature,” which is detected by electronic sensors. Once the signature is received by the computer, it cuts power to the saw motor and initiates a pressurized activation cartridge. The cartridge drives the blade arbor below the table at a high rate of speed, stopping an accident short.

While at first blush, this system may sound similar to SawStop’s patented design, there are several significant points of departure worth understanding. For one, unlike SawStop’s cartridges that embed an aluminum brake into the blade when an activation happens, Bosch’s REAXX technology doesn’t damage the blade.

“Once it’s below the table, a latch engages with the drop mechanism, preventing the blade from rebounding above the table surface,” Wilson says. “The blade naturally coasts to a stop. Due to the high speed that the blade drops, there is no need to incorporate a blade brake into the system. This is how we can prevent blade damage.”

Another difference between Bosch REAXX and SawStop involves the ability to re-use the cartridge. SawStop’s blade brake must be replaced after every activation. Bosch’s cartridge, by comparison, can be activated twice. The user must remove and turn the cartridge around, reinstall it, then reset the drop mechanism before continuing to use the saw. However, the entire reset process can be accomplished in around a minute, Bosch calculates. That means downtime and loss of productivity are kept to a minimum.

Wilson reports that the REAXX two-activation cartridges will sell for $99.

By comparison, a search of SawStop’s website will show that currently, its single-use blade brake cartridges cost $69 for a standard blade or $89 for a dado blade set, plus the cost of the replacement blade.

REAXX will accept standard 10-in. saw blades and both 8-in. and 6-in. stacked dado sets with full- or half-head chippers, but the tooth surfaces must be unpainted to allow the electrical current to flow and Active Response Technology to work. The saw is not designed for use with wobble-type dado sets or molding heads, and dado blades cannot weigh more than 8 lbs.

The GTS1041A is programmed for up to 25 skin activations, although Wilson says the saw’s system is built for a lifespan well beyond that number. After 25 activations, the tool becomes inoperable and must be taken to a factory authorized service center for inspection and service. The saw will notify the user that it is within one activation of needing service when a blue light on the display panel begins to illuminate.

In that regard, Bosch intends that the LED light panel on the new REAXX Jobsite Table Saw will be easy to understand, because it’s loosely based on traffic light directives. A green indicator means the saw is ready for use. A yellow light shows that the saw is set for bypass mode by the operator. Bypass allows the saw to cut conductive materials like wet wood or nonferrous metal without initiating the Active Response Technology. A red light means the saw will not function until the user corrects an issue, and blue indicates that service center attention is required.

Some initial media reports about the new REAXX saw suggested that the saw’s activation cartridge was borrowed from Bosch’s Automotive Group as crossover design, but Wilson says that claim isn’t accurate. It was developed within the power tool division. “While it does have similarities to the technology found in airbag initiators, the activation cartridge was designed for table saw activations,” Wilson clarifies.

Bosch has been investing substantial resources into the REAXX table saw project for more than 10 years, Wilson reveals, but the essential saw owes some of its pedigree to Bosch’s award-winning 4100 table saw series. The new GTS1041A will have a 4hp max-developed universal motor, featuring soft start, constant response electronics and overload protection. Its cast-aluminum table is sized to rip up to 25-in., and a pull-out extension will offer 18 in. of additional workpiece support behind the machine. Bosch includes its Smart Guard blade guard for added protection, a T-square style SquareLock™ Rip Fence and a Gravity-Rise Stand™ with 8-in. treaded wheels. The saw, with stand, weighs 123 lbs.

Given Bosch’s success in the jobsite table saw market already, Wilson says it was a natural category for positioning the new REAXX saw. And, while Bosch doesn’t currently build contractor or cabinet style table saws, those options may not be completely out of the question in the future.

“We’re always exploring different technologies and how they might be implemented across our portfolio. As we explore this technology across various platforms, we will be mindful of user interest and demand.”

Interestingly, Bosch is also willing to license the Active Response Technology to other saw manufacturers. “We would take any inquiries from third parties under consideration,” he adds.

Some may balk at the saw’s projected $1,499 price tag, but Wilson feels the cost is justifiable, considering the additional safety features and performance REAXX will provide, plus the inclusion of the stand and outfeed support. It promises “cutting edge” technology with a design built to withstand the rigors and demands of daily jobsite use.

Wilson attributes the GTS1041A REAXX Jobsite Table Saw to “outside the box” innovation, which he says is typical for Bosch. Using both internal and external resources is “inherent” to the way Bosch approaches how it develops new tools, “and this project is a good example of that mindset.”

Learn more about the upcoming REAXX Jobsite Table saw, and watch a video of the saw in action, by clicking here.