Turning is fun, which is why so many woodworkers turn. Even professional woodworkers who don’t need the lathe for their regular work admit it’s the tool they turn to for pleasure. Still, there are a few gremlins. For those turning bowls, they include catches, tearouts, chattering and the interruption of having to constantly stop and resharpen.

When erstwhile construction worker and dog trainer Jack McDaniel turned bowls, he suffered through the same problems, but he decided to do something about it. He came up with a tool that eliminates all those problems, and appropriately enough, he named it “The Eliminator.” He liked it so much he decided to make more of them and sell them to his friends, which fortunately includes all of us woodworkers. How this all came about is firmly enmeshed in a somewhat convoluted trail that starts after his military days.

“After my stint in the Air Force,” Jack recounted to me, “I worked in construction for more than two decades, from 1958 to 1979. As luck would have it, I bought a farm in Moses Lake, Washington on May 16, 1980, just two days before Mount St. Helens blew its top and covered the entire farm with four inches of ash. The next year, my wife and I started showing dogs and training field dogs. We formed the Academy of Canine Behavior that embodies our approach to dog training: that dogs are like two-year-old children.

“Along about 1997, I started turning wood, my first venture into hobby woodworking. Initially, I decided I wanted to make a cane, so I bought a lathe and some tools. I had no idea how to turn, so I took lessons from a local woodturner. I was immediately hooked on turning, and soon joined the Seattle chapter of the AAW, of which I am currently president. Before long, I started turning bowls.

“Much of my work is making trophies, which I donate to various dog clubs. I never really intended to sell my turning work, but started JewelWood Studio about five years ago so I could buy supplies from companies that only sell to businesses. A little more than two years ago, I bought a CNC milling machine with an eye to using it for making trophies. Eventually, I added a CNC lathe.

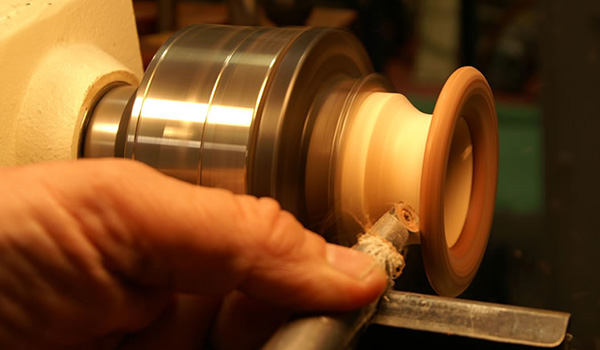

“Several people I know had been experimenting with scraper type hollowing tools. The problem is they tend to catch, tear wood and need sharpening frequently. I was looking for a better tool, one that would shear rather than tear wood, and realized that if you held a cutter at just the right angle, it cut beautifully. I took a carbide cup cutter from my metal lathe and mounted it on the end of a round bar, but quickly found that if the angle shifted to the wrong orientation, disaster could result. Working inside a hollow vessel, you had no idea what was happening since you could not see the cutter engaging the wood. There was no way to tell at what angle the cutter sat.

“I milled a flat on one side of the bar so that it would lie on the tool-rest at the correct angle. That worked great, but a lot of people, myself included, also cut with the lathe in reverse, which gives you more control. For that I needed a different angle, so I made two tools: a left and a right cutting tool. As I looked at it, I realized that if I cut two flats on one bar, I could get both functions in one tool. I called the tool The Eliminator because it eliminated all the common problems associated with deep bowl turning, including sharpening. Eventually I made three sizes, a small, medium and large.

“The bar on which the cutter is mounted is mild steel, which tends to absorb vibration better than harder steels. The smallest bar is a half-inch diameter with a quarter-inch diameter cutting bit. There’s also a three-quarter bar with a three-eighths cutter, and a one-inch with a half-inch cutter. The two smaller ones are 12 inches long, and the largest one is 16 inches long. I sell them with a tenon on the end that fits into the readily available handles on the market. That also makes them easier to break down for travel.

“For small boxes and hollow turnings, the small tool is perfect, and allows you a tiny eighth-inch radius. The Eliminator will also work on the outside, and is perfect for cutting coves. Unlike standard tools that force you to cut coves downhill from two directions, this tool lets you cut outside coves in one sweeping motion. It’s also great for cleaning up bottoms of bowls since it allows you to make elegant finished radii without fear of messing up the piece at the final stage. It’s really divine down at the bottom of bowls. The medium and large cutters allow you more stability during deeper cuts, but offer the same control and advantages. The only difference is that you will have a larger radius of cut.

“At first I started selling them to my fellow guild members. The company is only a year and a half old, and I have sold over 500 of them. Recently, two wood turning specialty companies, Packard Woodworks and Crafts Supply, picked them up, as did a single woodworking specialty store. Because of those arrangements, I do not sell direct from my web site.

“The tools are manufactured right here in Bothell, Washington on my own CNC machines, which makes quality control easy to manage. I’m much more interested in producing quality than volume. I have a part-time helper but, for the most part, if you own one of my tools, it came from my hand. I personally assemble each by hand and check every one before it goes out.

“I do a demonstration with the largest cutter in which I mount a bowl blank on a mini lathe, set the rest out 13 inches away, and with one hand, make a perfect cut. The point I am making is that you can easily cut 13 inches into a large bowl with no worries.

“However, the coolest aspect of this tool is that I can take a person who has never touched a lathe, put the tool in their hands without worrying about them hurting themselves, and watch as they make a perfect cut the first time out. It’s almost foolproof used the way it was designed.

“Try it,” Jack summed up with assurance. “You’ll like it.”