As the saying goes, there are three unavoidable things in life: death, taxes and wood movement. And the irresistible force of wood movement is exactly why the frame-and-panel technique for solid wood construction was invented hundreds of years ago.

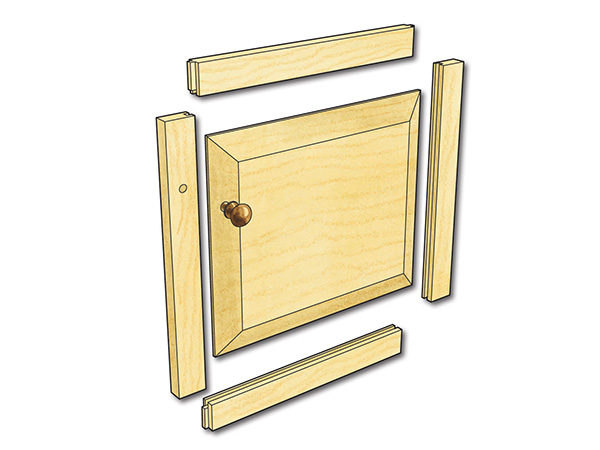

Raised Panel Doors

|

Before that, large panels of wood were mostly edge glued (but not always) and likely had long strips of metal across their face to try to keep them together and from distorting. If a frame was attached around a panel, that panel was always more powerful than its constraints.

Then some brainy person figured out the predictability of wood’s expansion and contraction, especially of wooden panels, and came up with a way to accommodate it.

A Combination of Factors

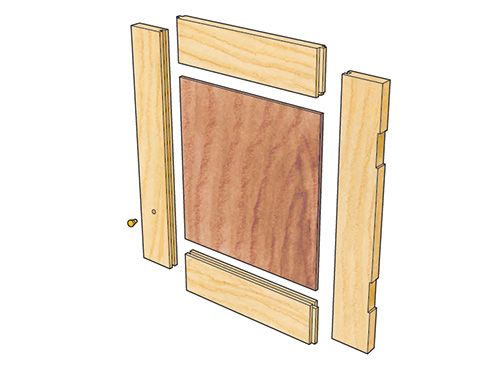

Raised Panel Doors – Corner Joint Variation

|

Wood moves in a couple of different directions, particularly across its grain. The wider the panel, the more it expands and contracts and the more problematic it can become when housed inside a frame. By comparison, wood expands and contracts much less across the grain of a narrow piece of wood. That’s why what we now know as rails and stiles of cabinet doors are made from narrower strips. Neither panels, rails nor stiles move to any significant degree along their grain, or end-to-end as you might describe it.

Joining Stiles and Rails

Flat Panel Doors

|

The key to making a solid door frame is to create durable corner joints. This is done most commonly with a mortise-and-tenon joint, which has a geometry that is hard to beat for this task. The mortise is a socket that captures a protruding tenon. If made properly, tenons will have a gentle friction fit in their mortises, and their shoulders will engage tightly against the mortised stock. The joint becomes even more durable when glue and pins are added to it.

Because humans are incredibly creative, there are many variations of frame joinery, including bridle joints, loose tenons, dowels and more. They all get the job done in their own way.

In recent years, pocket hole joinery has become another method of making frames quickly and practically, but their angled screws likely won’t have the long-term durability of a classic mortise-and-tenon. Even so, pocket screw joints sure are handy!

Panels

Glass Panel Doors

|

Panels are the largest and most dominant component in a frame-and-panel door, but they receive no joinery. Instead, the frame-and-panel system enables the wood panel to pretty much do what it does — expand and contract across its width. For that reason, the panel is typically captured in grooves plowed along the inside edges of the stiles and rails so it can “float” and move.

Wooden door panels usually are flat or have raised center fields, possibly with carvings. Other panel options include glass, mirror, metal or even ceramic.

Frame-and-panel construction was one of the biggest advancements in the craft of woodworking. It is so successful that when we think of a cabinet door, it comes to mind almost immediately.