Many building contractors and DIYers use portable table saws on their jobsites or around the house and yard. They’re ubiquitous, economical and convenient to transport. But, these small and lightweight saws typically trade full-size and more robust features for compactness and to help shed mass. And, while some portable table saws are attractive due to budget pricing, the tradeoff is that they may be more difficult to operate accurately and safely. Rip fences don’t always stay parallel to the blade. Miter gauges are undersized, offering poor workpiece support. Anti-kickback features are difficult to align behind the blade … and the list can go on. Still, “jobsite” style table saws are the most practical option for those who require a saw to move with every project or building location.

Jobsite situations can make table saw use more challenging in its own right, too. Workers aren’t always trained on the safe operation of a table saw. The pace and demands of the work situation might prompt some users to work unsafely. Or, just the sheer frequency of using a table saw day in day out in often less-than-optimal conditions increases the chances for a workplace accident to occur. Pair this with a saw that may be of marginal quality, and the prognosis isn’t good.

“I was at a (professional builders show) last week in Portland,” says Matt Howard, vice president of marketing at SawStop. “During a demo, I asked the audience how many knew someone who had had a table saw amputation. Out of a crowd of around 40, every single attendee raised their hand. Every single one.”

That’s why in March, SawStop intends to raise the bar of both safety and accuracy of portable saws when its all-new Jobsite Saw ($1,299 street) reaches distributors’ showrooms. Some details about the machine have been shared publicly already, but Howard was happy to provide more details for our eZine readers now.

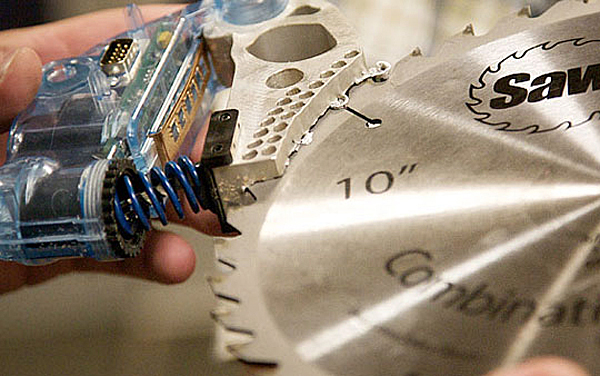

First and foremost, the new Jobsite Saw will come equipped with skin-sensing technology that can stop the blade in milliseconds, preventing mishaps from becoming tragedies. In the event of a body part coming in contact with the spinning saw blade, an internal computer engages a brake that embeds in the blade and stops it, while also lowering the blade below the table.

“The saw uses the same standard blade and dado cartridges as other current SawStop saws,” Howard reports. “The safety technology is essentially the same.”

So, even if a user is sawing with the guard and riving knife in place, the skin sensing braking system will offer a big step forward in safety for small, portable table saws. No other jobsite saw on the market is so equipped.

Howard says the brake cartridge can be installed or removed easily through the saw’s throatplate opening, in the same fashion as other larger SawStop table saws. And, this new Jobsite Saw can also accept an 8-in. dado blade for cutting dadoes up to 13/16-in. wide. For dadoing, SawStop’s dado brake cartridge must be installed. A zero-clearance insert will also be available for dadoing.

Jobsite users often cut wet framing lumber or pressure treated material. In those situations, the operator can effectively “ask” the saw’s computer whether a material is too conductive, which could unnecessarily activate the blade brake. Lights on the saw’s oversize kill switch in front will tell the user if the saw should be set to bypass mode using a key, for making wet-material cuts, or if it can be switched back to the safety mode with the brake system engaged.

“One of the features of the saw outside of the safety system I’m most excited about is the rip fence,” Howard adds. “It glides smoother and locks down easer and firmer than any other fence I’ve used.”

The rip fence is T-style in design with a unique ErgoLock feature along its top edge. Rather than the typical locking lever in front on the fence’s clamping mechanism, ErgoLock is an inline rocker paddle. Locking the fence can be done with a finger push, and unlocking the fence to reposition it happens by pushing the same paddle down in the opposite direction with a palm. Howard says there are two advantages to the design: the first is efficiency. A user controls the fence’s position and lock down without changing hand positions. Second, ErgoLock prevents the fence from “jumping” out of position when the lock is released; it’s a common problem with other rip fences on lightweight saws that can throw off their position on the fence rails.

The Jobsite Saw offers up to 25-1/2 in. of ripping capacity by extending the saw’s fence rails to the right of the table. A ledge can be projected out from the inside edge of the rip fence to support wide workpieces.

Dialing in blade settings is easier, too, on the 10-in. Jobsite Saw. Unlike all other table saws, jobsite and otherwise, this saw enables you to raise or lower the blade throughout its full range of travel (up to 3-1/8-in. of cutting height at 0 degrees) in just a single revolution of the hand wheel. Some saws require up to 25 cranks. Tilting the blade left off of 0 degrees is easy as well: squeezing a paddle behind the blade tilt wheel allows you to move the handwheel along its protractor scale to adjust the tilt. A separate “MicroTilt” control on the front of the saw engages the trunnion to adjust the blade between single degrees of tilt. This amount of micro-adjustability is an industry first on a jobsite saw, too.

During cutting, the saw’s 1.5hp, 15-amp universal motor develops a peak output of just over 3 horsepower, Howard reports. The tool can be connected from a port in back to a standard shop vac hose, to help contain the dust.

A scissors-style tubular steel stand with 8-in. treaded wheels makes the 79-lb. saw (108 lbs. with the cart) easier to roll around, dolly-style, and it sets up quickly to a 36-in. working height. It folds down for transport or storage by pushing one lever.

Other user conveniences include a full-size, plastic bodied miter gauge, an onboard storage drawer for accessories and an amply-sized, power-coated aluminum tabletop that measures 31-1/4-in. wide by 22-5/8-in. deep. A detailed list of specifications can be found on SawStop’s website by clicking here.

Howard says the development process for this new Jobsite Saw has taken many years, because its trunnion and braking technology are unique to SawStop: the company can’t use existing engineering as other manufacturers often do. But, that’s what makes its design truly groundbreaking. And, from a safety standpoint, the skin-sensing technology has been sorely needed by construction professionals in the portable saw category.

“All the operators who raised their hands, who know someone who has been injured on a table saw or have been injured themselves, need the protection that only we can provide. When they buy a SawStop Jobsite Saw, they will be safer. And they’ll be operating the best portable saw they’ve ever owned. We can’t wait to get started.”